Additional information

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |

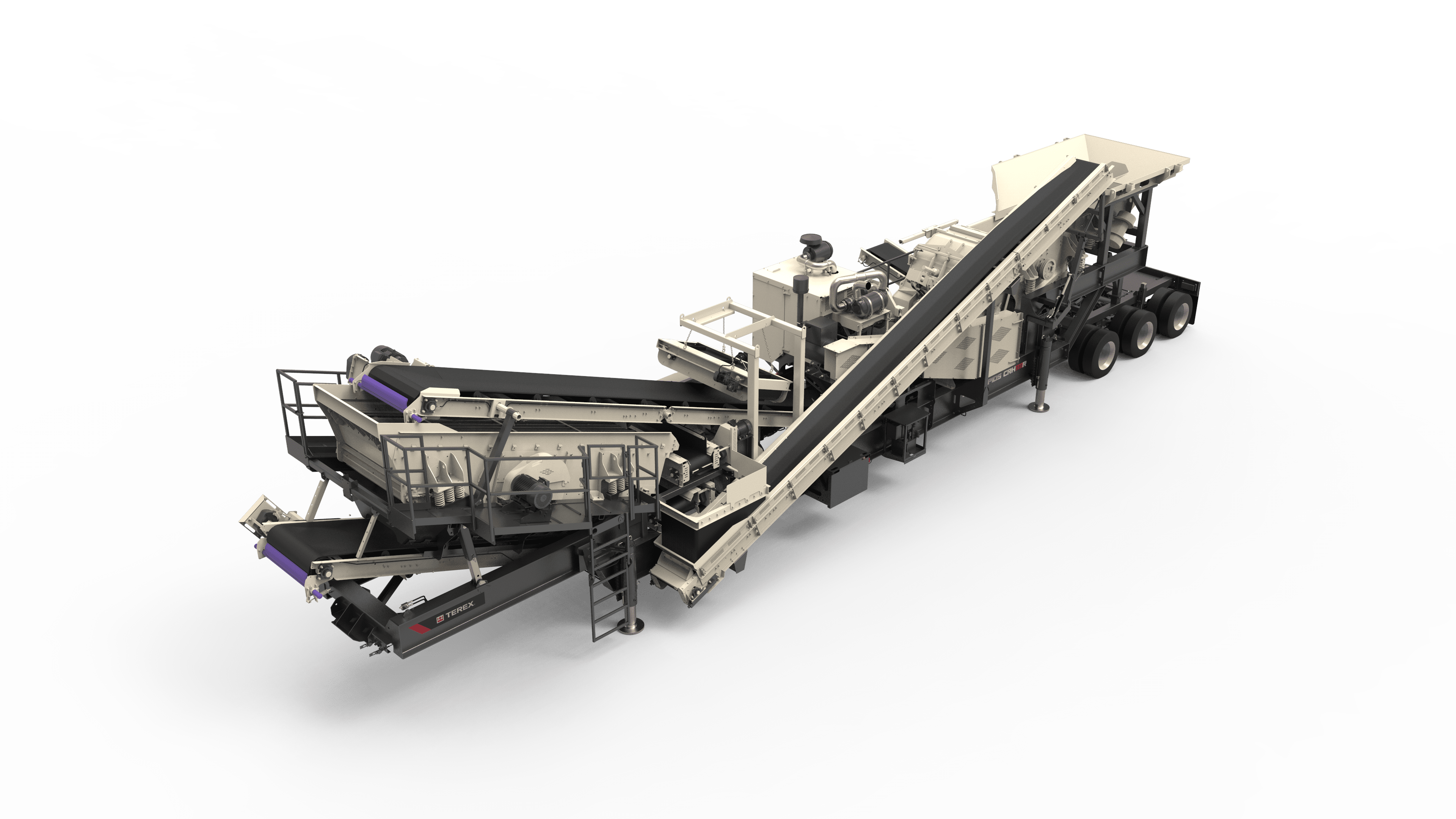

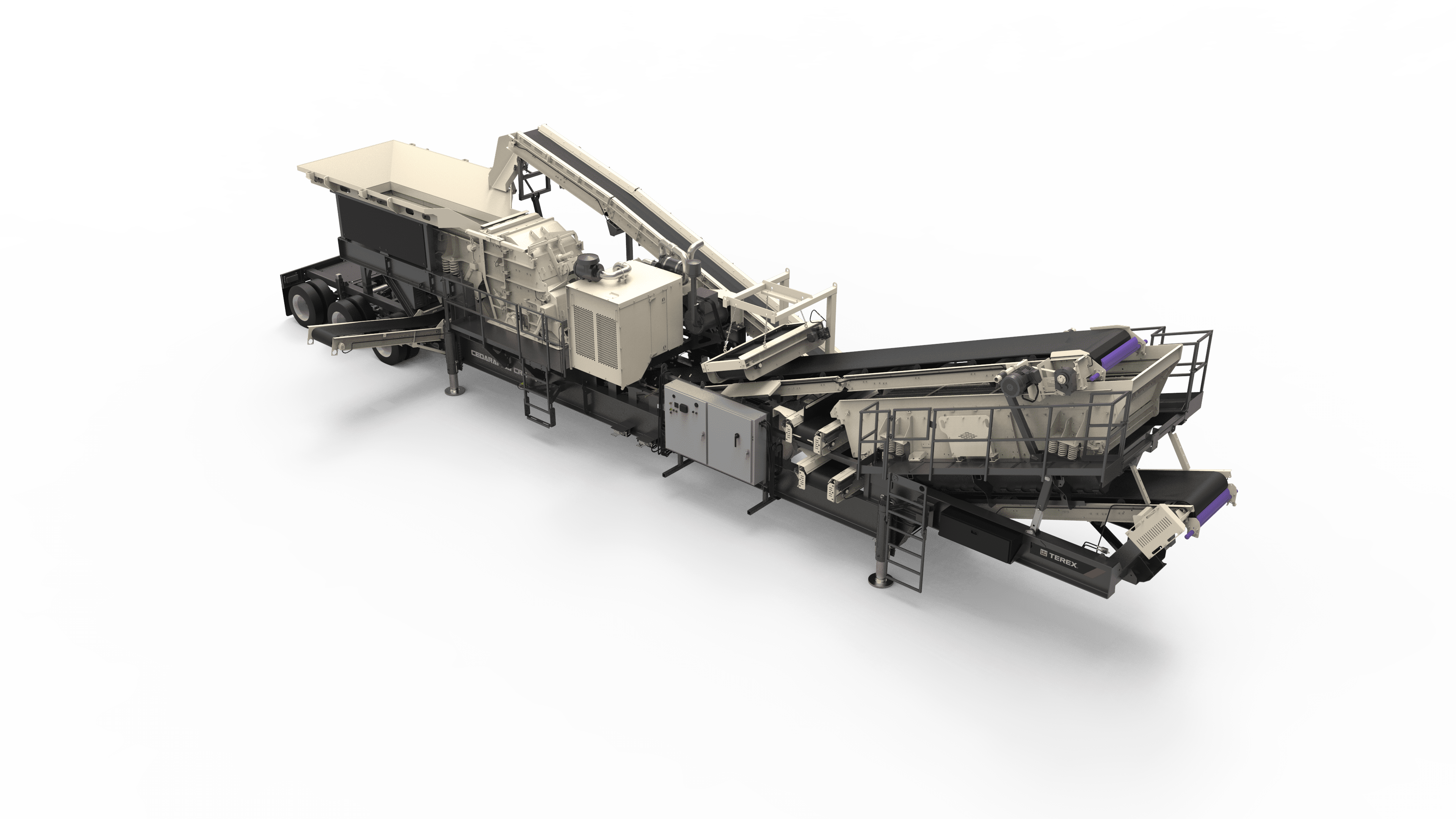

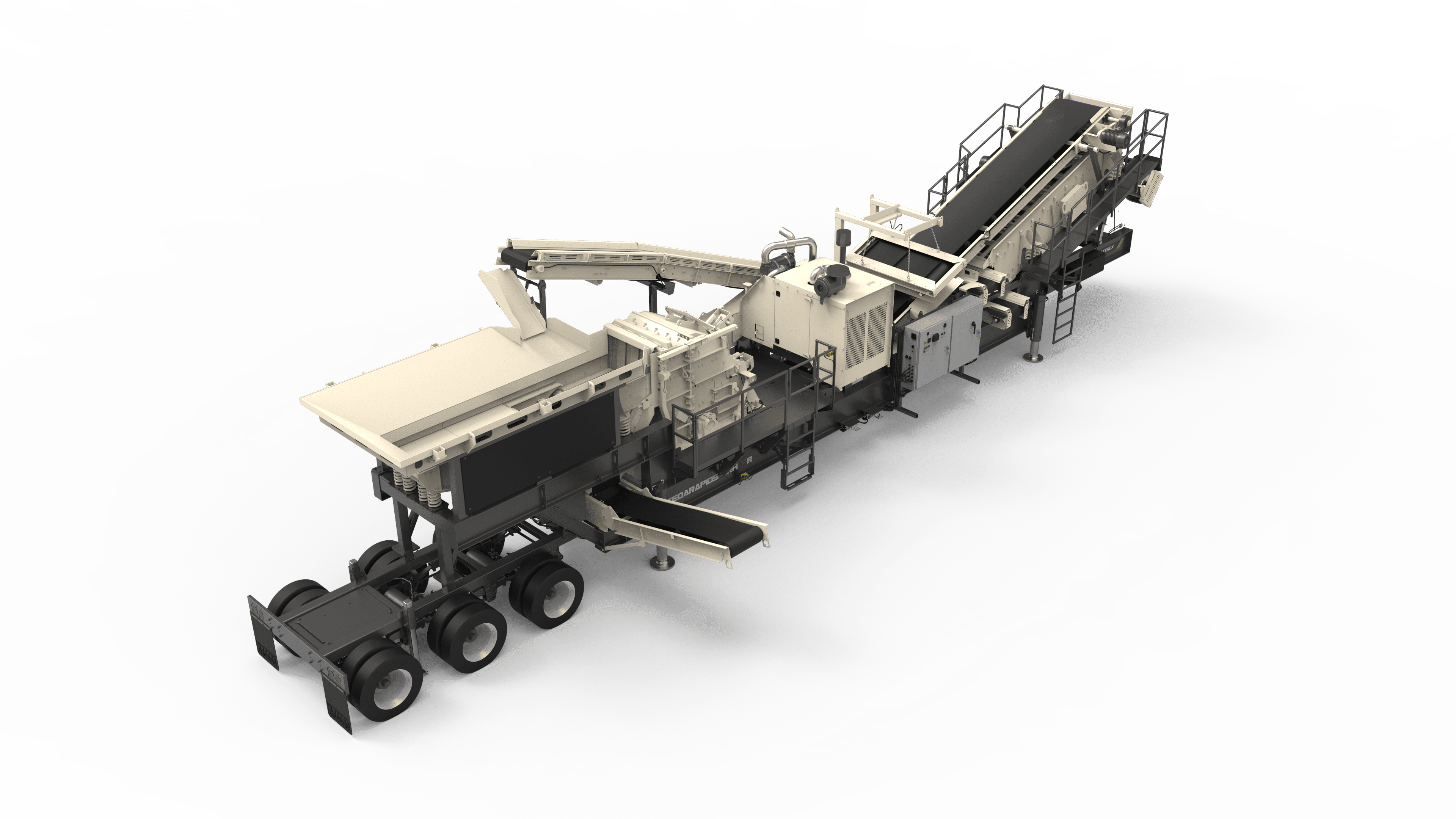

The CRH1111R Portable Closed Circuit Cone/Screen Plant features the TI4143 impact crusher and a 5×16 2-deck inclined screen. The crusher is hydraulic clutch driven direct from a 350hp Scania diesel. All other components are electric driven from the 150kw generator. With its large screen, wide conveyors, and low maintenance electric driven components , this is a highly productive, high value plant.

Get More InfoApplication: Aggregate

Manufacturer: Cedarapids

Configuration: Portable (Wheeled)

Model: Cedarapids CRH1111R Portable Impact Crusher Plant (HSI)

New/Used: New

Standard Features

Optional Equipment

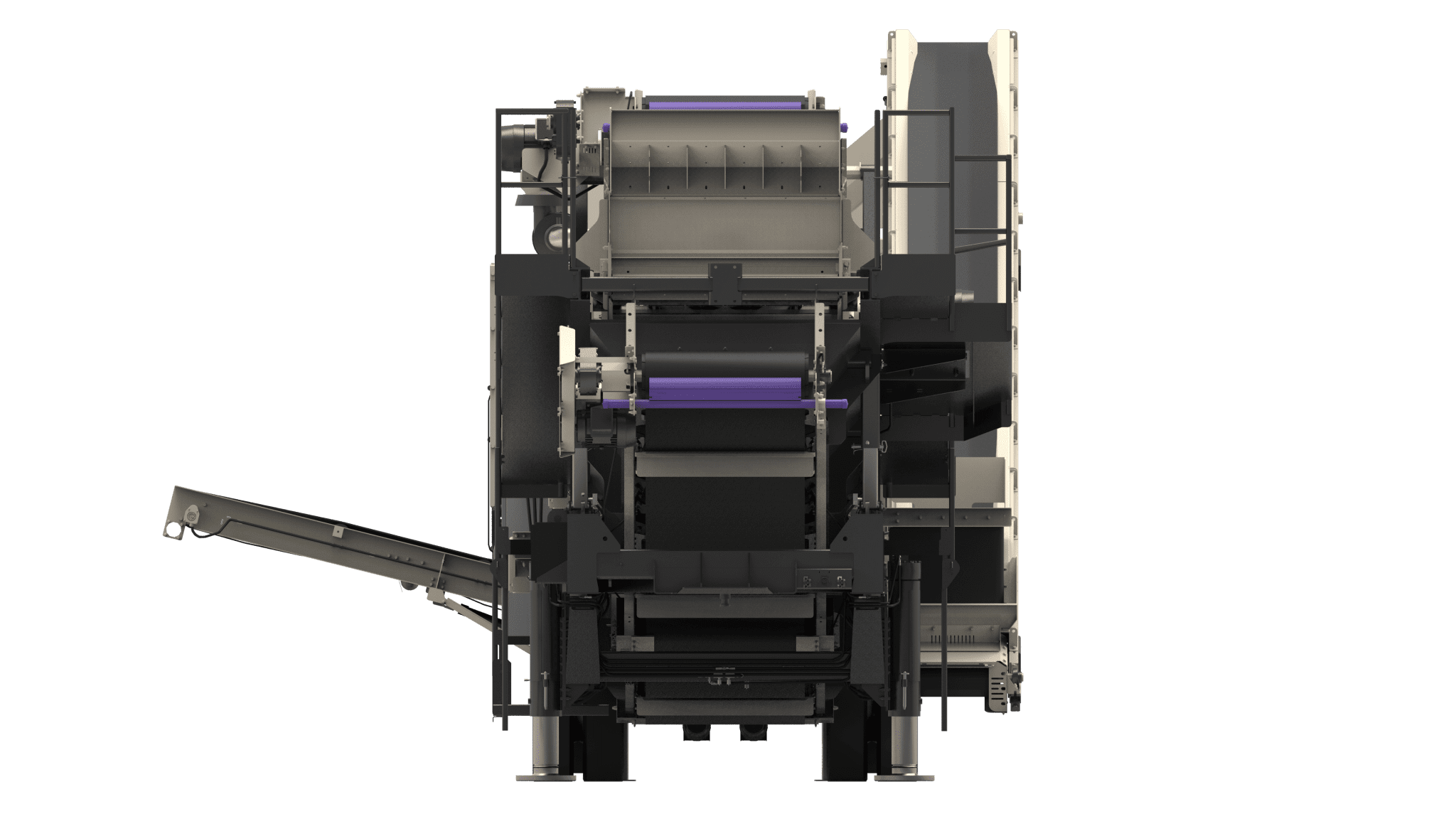

The CRH1111R horizontal shaft impact crusher is equipped with a large 5 x 16 two-deck inclined screen for the production of high-quality spec aggregates. This smaller one-piece plant is easy to transport and offers a larger screen deck than most tracked units.

The CRH1111R closed circuit impact crusher is designed with high capacity conveyors throughout the machine for high production applications with consistent material flows. This includes Cema C class belt components, rubber disc returns, guide rollers, and a 3-ply vulcanized belt for increased bond strength, longevity, and durability. The undercrusher screen feed conveyor is made with HD 600 PIW.

Features such as the 11.2-yard hopper, TI-4143 impact crusher, 350 hip engine, 24″ cross and return conveyor, 5′ x 16′ double deck screen, and large return and reversing conveyors, make the CRH1111R ideal for high production quarry applications.

The elevated discharge conveyors feed directly off the CRH1111R impact crusher to allow for easy clean up with no digging of holes required. The fines conveyor is 8′ 7″ off the ground,m while the bottom deck cross conveyor is 5′ above ground and rolls out for the operation.

With almost 200 years of crushing and screening manufacturing experience, Cedarapids delivers rugged, field-proven crushing and screening solutions. Cedarapids® Crushing & Screening Plants offer the essential flexibility, control, and reliability to make the difference – whatever the application, wherever the location.

Cedarapids® Crushing & Screening Solutions Cedarapids® provides a complete range of crushing and screening equipment to customers around the world operating in four key industries: mining. aggregates. demolition and recycling. To date they have thousands of plants operating througout the globe are known for equipment designs and technologies which are built to last.

“With Cedarapids®, you don’t just get best-in-class engineering technology. You get the service, training and support to match. They understand owners needs to maximize productivity and control operating costs across the working life of every piece of equipment. This means you can count on engineering technology that delivers in terms of maintenance access, longevity, and cost per tonne.”

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |