Additional information

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |

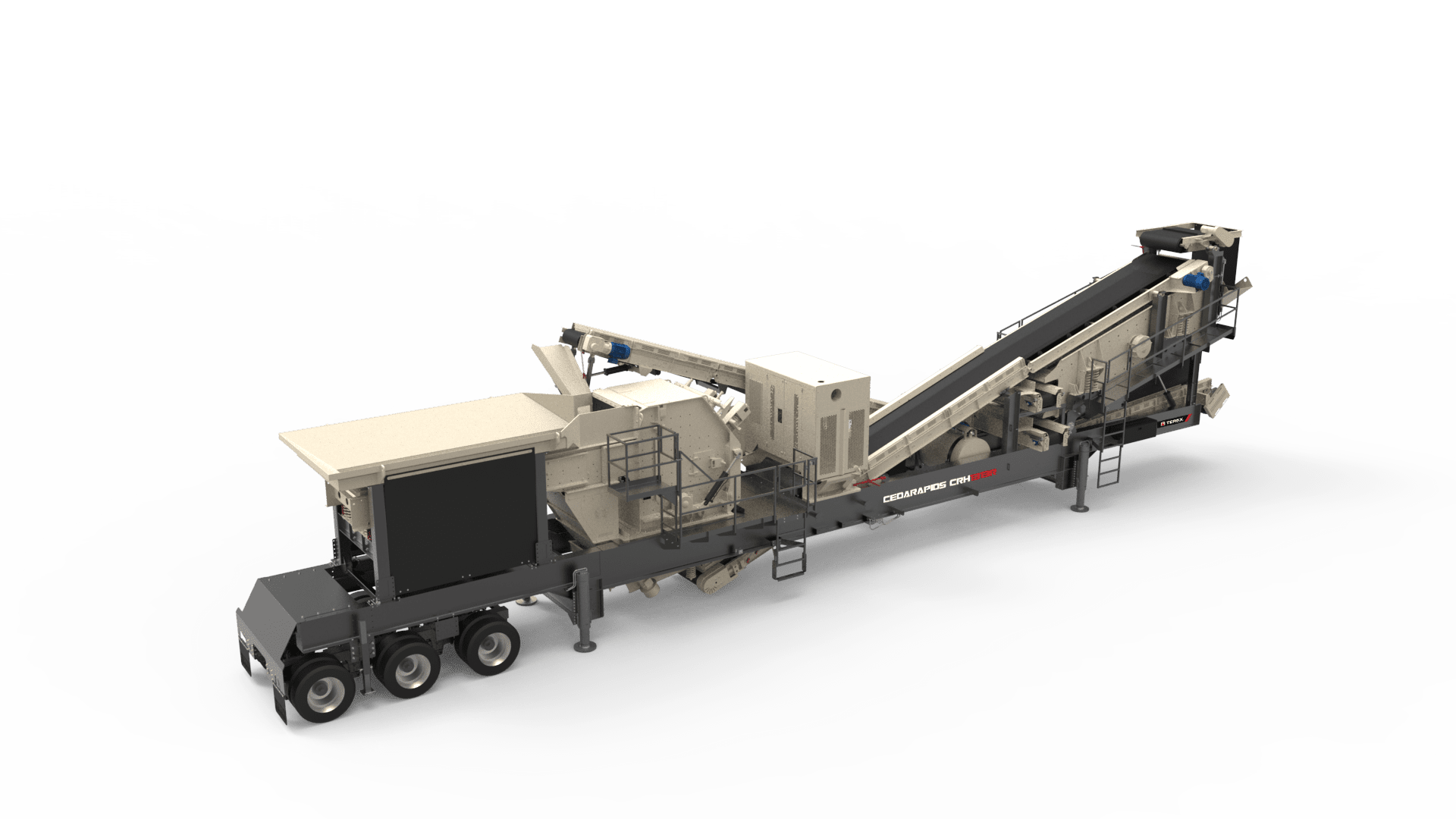

The Cedarapids® CRH1313R delivers big production and has the versatility to handle rock crushing, concrete recycling, and asphalt recycling. The highly mobile plant is a complete stand-alone closed-circuit unit with three product capability. The plant features a high production Cedarapids IP1313 impactor with a 3 or 4 bar 50” (1270 mm) rotor powered by a Tier 4, 450 hp (335 kW) diesel engine, direct drive to crusher, and 200 hp (150 kW) generator. Uptime is maximized with a heavy-duty undercrusher pan feeder that protects the conveyor belt from damage by absorbing the high velocity discharge from the crusher. More capacity is possible because of the 5’x16′ (1515 x 4875mm) patent-pending dual-slope 2-deck screen which handles heavier loads. In addition, the capability to return both screen deck products to the crusher maximizes production. A rugged 48″” x 16′ (1220 x 4875 mm) high-stroke Cedarapids “Advantage” feeder with 60″” (1525 mm) grizzly bar or optional stepped tine style grizzly section feeds the impactor. The new CRH1313R portable impactor/screen plant is simple to operate, quick to set up, and easy to transport.

Get More InfoApplication: Aggregate

Manufacturer: Cedarapids

Configuration: Portable (Wheeled)

Model: Cedarapids CRH1313R Portable Impact Crusher Plant (HSI)

New/Used: New

Standard Features

Optional Equipment

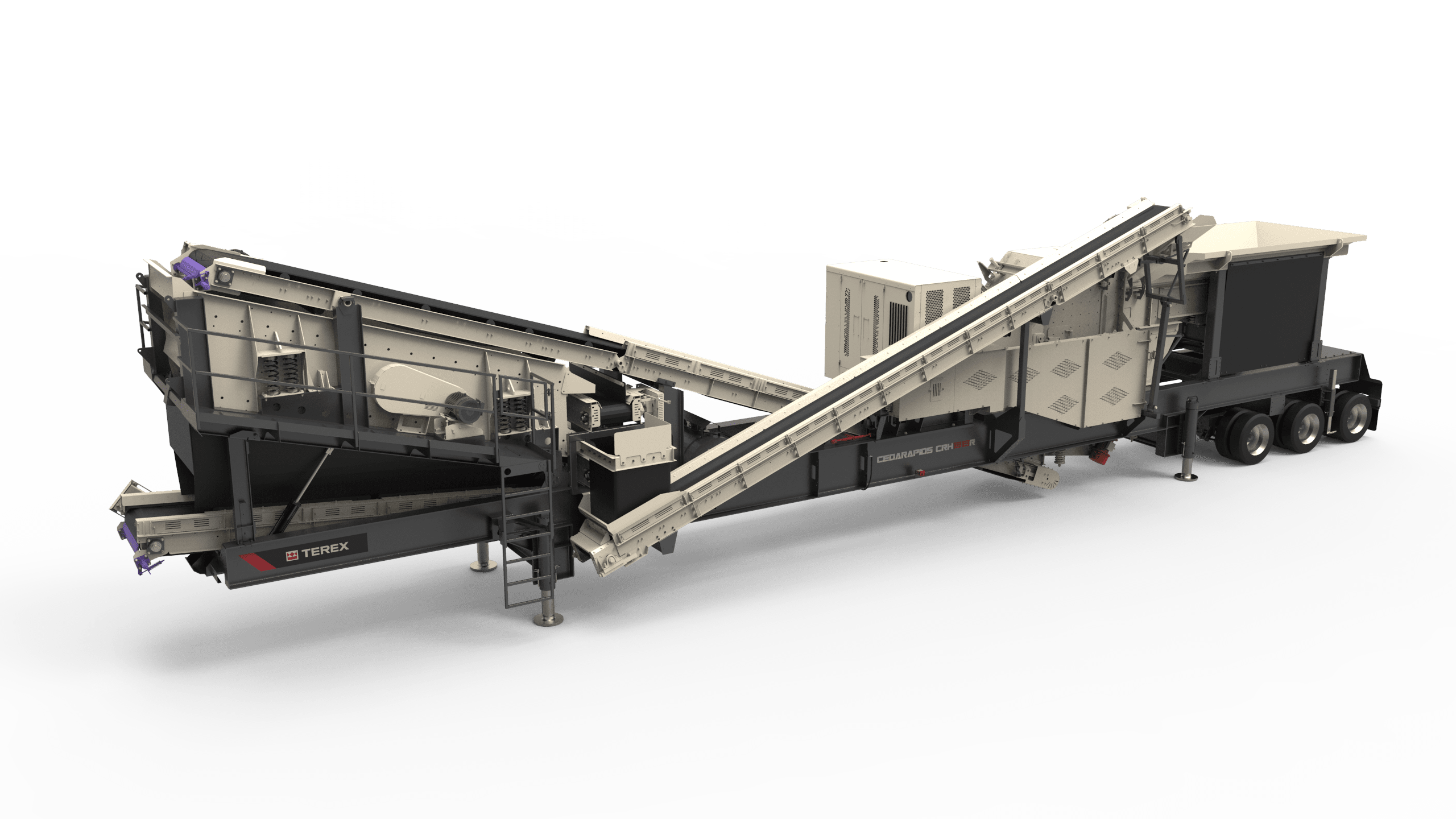

If portability is important for your crushing business, look no further than the CRH1113R horizontal shaft impactor. This self-contained unit offers a 1-piece tow system on a 4-axle chassis with an optional 3+1 axle. Fast and easy to use hydraulics offer timely and efficient site set up.

The CRH1113R bodes a highly unique 6′ two-deck grizzly. The convertible grizzly can be equipped with various cassettes including stepped fingers, a finger and sloped punch plate, or a sloped punch plate.

The multi-function remote control displays and controls critical functions of the impact crusher including the percentage of speed, fault messages, plant auto on/off, feeder on/off, and feeder speed adjustment. Additionally, it can control up to 2 auxiliary devices independently such as a radial stacker or dust suppression system.

Cedarapids crushing and screening plants are designed with maintenance in mind. The CRH1113R impact crushing plant features convenient maintenance access, hydraulic overhead conveyor lift access, open access below the mainframe for easy cleanup and an all-electric drive providing a long low maintenance lifespan.

With almost 200 years of crushing and screening manufacturing experience, Cedarapids delivers rugged, field-proven crushing and screening solutions. Cedarapids® Crushing & Screening Plants offer the essential flexibility, control, and reliability to make the difference – whatever the application, wherever the location.

Cedarapids® Crushing & Screening Solutions Cedarapids® provides a complete range of crushing and screening equipment to customers around the world operating in four key industries: mining. aggregates. demolition and recycling. To date they have thousands of plants operating througout the globe are known for equipment designs and technologies which are built to last.

“With Cedarapids®, you don’t just get best-in-class engineering technology. You get the service, training and support to match. They understand owners needs to maximize productivity and control operating costs across the working life of every piece of equipment. This means you can count on engineering technology that delivers in terms of maintenance access, longevity, and cost per tonne.”

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |