Additional information

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |

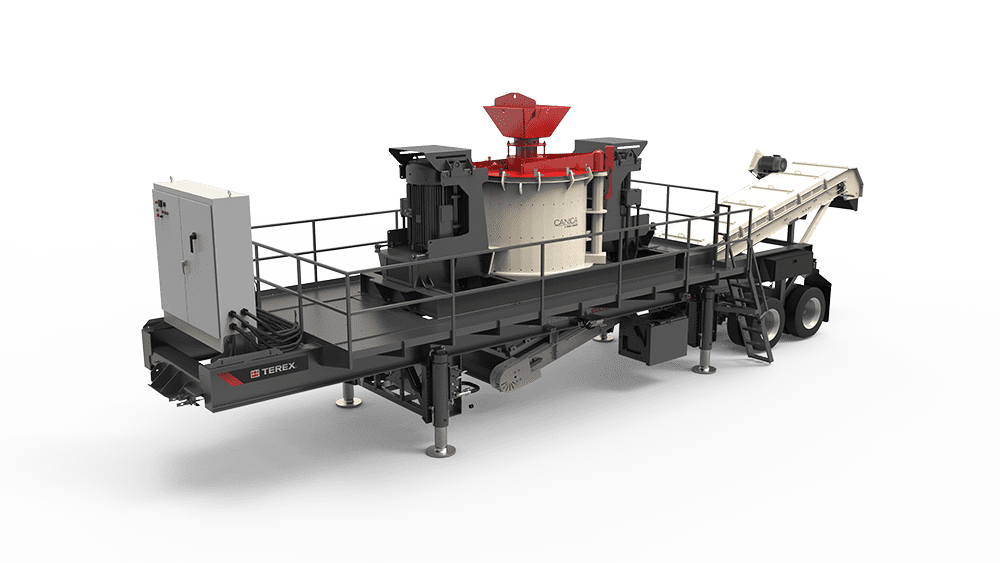

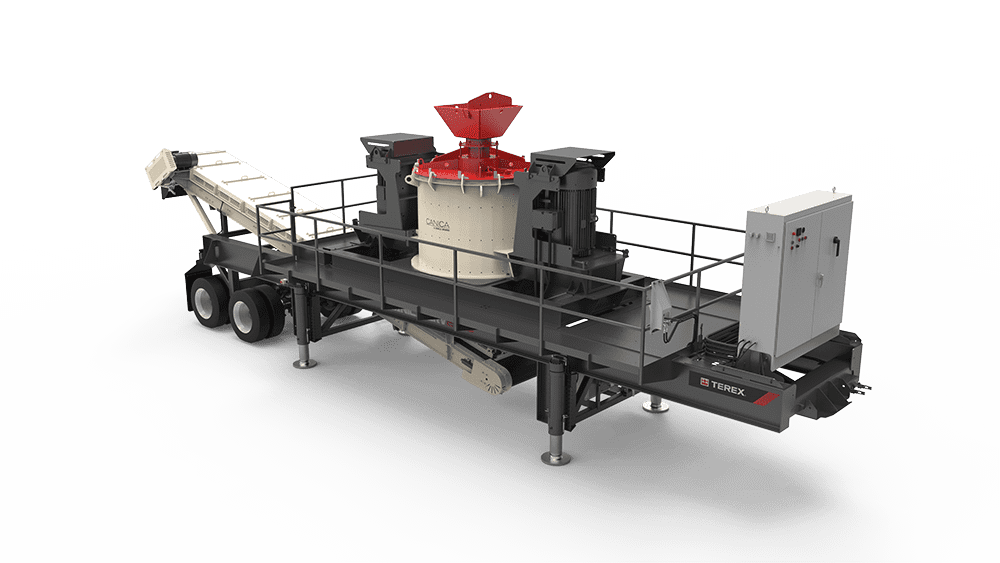

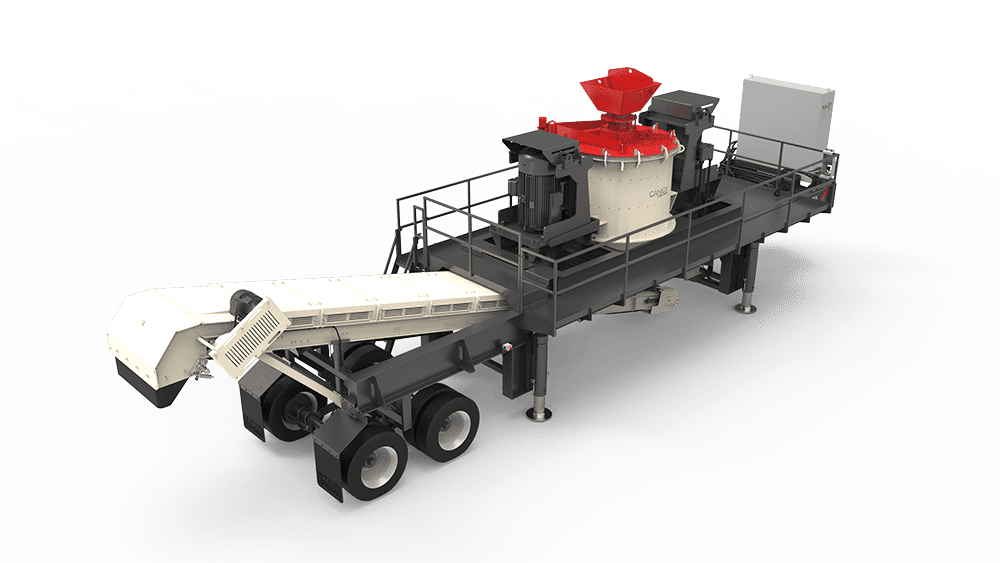

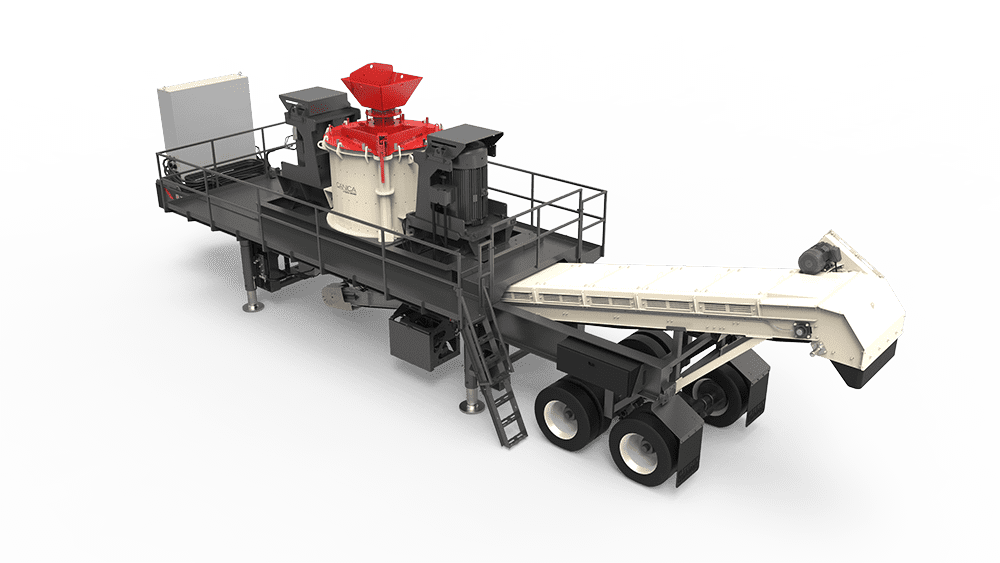

The CRV2000 portable VSI features the world renowned Canica 2000 Vertical Shaft Impactor, available in a number of chamber configurations. This highly mobile all electric plant comes with our latest CCM automation system and is available in both single or dual drive.

Get More InfoApplication: Aggregate

Manufacturer: Cedarapids

Configuration: Portable (Wheeled)

Model: Cedarapids CRV2000 Portable Impact Crusher Plant (VSI)

New/Used: New

Canica CRV Series Standard Features

Crusher

Modular Oil System

Ancillary Electrical Control Cabinet

Standard Safety Features

Crusher Optional Equipment

Plant Optional Equipment

The interchangeable table and rotor options on the CRV2000 vertical shaft impact crusher plant offer maximum application flexibility.

The CRV2000 VSI produces superior cubical with the ability to control product grading. It improves the soundness and shape of the stone as well as reducing product moisture helping to prevent screen build-up.

The CRV2000 vertical shaft impactor features standard safety features such as an open lid safety lock and a shut-off switch detection monitoring low oil pressure, excessive vibration (vibration switch), and open lid.

The use of a Variable Frequency Drive (VFD) can make a VSI more flexible to produce a number of products from the same application by raising or lowering the rpm to fine-tune the discharge.

With almost 200 years of crushing and screening manufacturing experience, Cedarapids delivers rugged, field-proven crushing and screening solutions. Cedarapids® Crushing & Screening Plants offer the essential flexibility, control, and reliability to make the difference – whatever the application, wherever the location.

Cedarapids® Crushing & Screening Solutions Cedarapids® provides a complete range of crushing and screening equipment to customers around the world operating in four key industries: mining. aggregates. demolition and recycling. To date they have thousands of plants operating througout the globe are known for equipment designs and technologies which are built to last.

“With Cedarapids®, you don’t just get best-in-class engineering technology. You get the service, training and support to match. They understand owners needs to maximize productivity and control operating costs across the working life of every piece of equipment. This means you can count on engineering technology that delivers in terms of maintenance access, longevity, and cost per tonne.”

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |