Additional information

| Application | Aggregate, Construction & demolition, Soil, mulch & compost, Waste & recycling, Wood recycling & forestry |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |

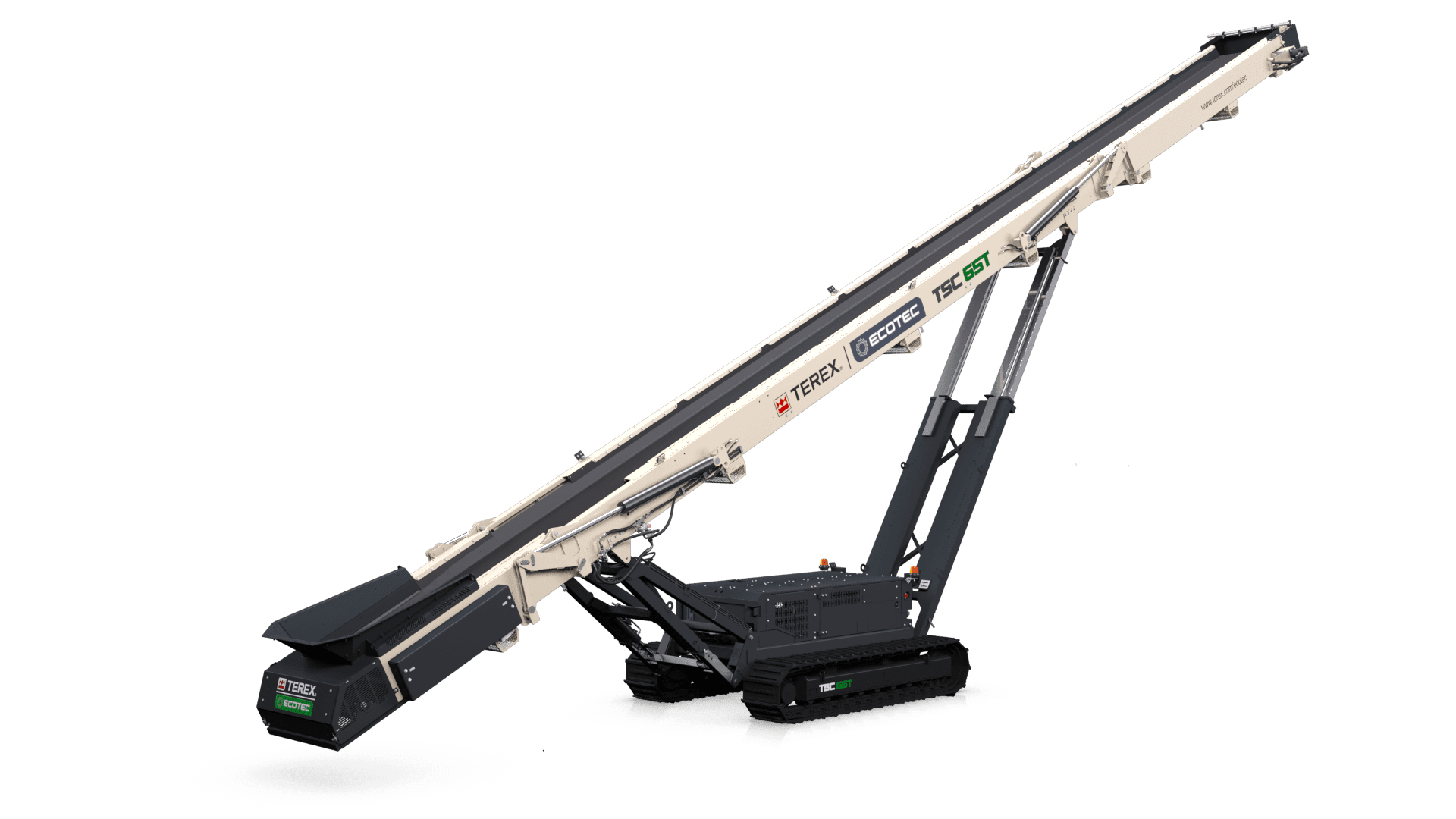

The TSC 65T is a self-powered 65ft tracked stockpiler with impressive features and conveying capacities. The intelligent design allows the machine to be folded small enough to fit inside a 40ft container and be shipped cost effectively globally.

The track in and out design lets operators simply track the machine out and fold into the working position and start conveying material. Hydraulic angle adjustment and belt speed adjustment ensure optimum performance in every application. Maximum discharge height of 8.7m (28’ 6”) and capacities of up to 400tph position the TSC 65T as a leader in the industry.

Get More InfoApplication: Aggregate, Construction & demolition, Soil, mulch & compost, Waste & recycling, Wood recycling & forestry

Manufacturer: Ecotec

Configuration: Mobile (Tracked)

Model: Ecotec TSC 65T Tracked Stacking Conveyor

New/Used: New

Performance Highlights;

Options

*Varies depending on conveyor length. See detailed specification for each conveyor

The hydraulic 0° to 28° angle adjustment for variable feed heights reduces impact and provides optimal material transfer from almost any other plant.

The intelligent design allows the machine to be folded small enough to fit inside a 40ft container and be shipped cost effectively globally. The track in and out design lets operators simply track the machine out and fold into a working position and start conveying material.

Terex Ecotec’s mobile conveyors come standard with a steel-lined feedboot providing extended wear life. Feedboot extensions and rubber lined options are also available.

Fully protected Deutz TD2.9 L4 – 41 kW (56 hp) power-unit provides easy ground access for service and maintenance.

Ecotec’s broad range of equipment allows for more targeted efficiency in niche operations. Behind an aggressive research and development strategy, Terex Ecotec now offers a full product portfolio that meets the needs of today’s professionals and will shape the industry for years to come. The Terex Ecotec product line has grown significantly and expanded production out of a new 105,000 square foot manufacturing facility Today their comprehensive product portfolio includes, Slow, Medium & High Speed Shredders, Trommel Screens, Recycling Screens, Waste Handlers, and conveyors.

Ecotec is your proven industry-leading partner for the design, service, and support of primary waste recycling, wood recycling, and composting equipment. They have dedicated sales and service staff for the Ecotec product range with a driving focus on providing customers the best support in and out of the field. Their world-class dealer distribution network provides the sales and aftermarket service demanded in the marketplace giving customers the support required to maximize production and minimize downtime.

Terex® Ecotec, part of the wider Terex Materials Processing group, is an industry leader in the design and manufacture of wood processing, biomass, and recycling equipment. The range of innovative machines available is robust yet user-friendly with a focus on throughput, efficiency, and serviceability. Their world-class range of mobile equipment that will shape the industry for years to come.

| Application | Aggregate, Construction & demolition, Soil, mulch & compost, Waste & recycling, Wood recycling & forestry |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |