Additional information

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |

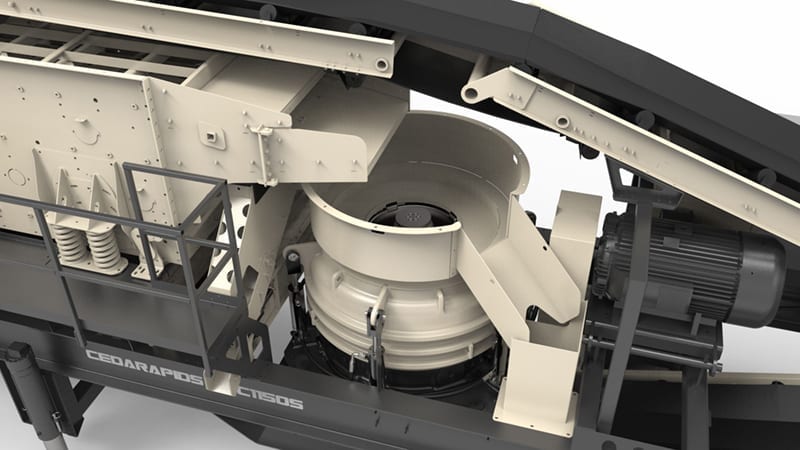

The CRC1150S cone plant delivers big capacity features in an economical highly portable plant. The highly mobile plant combines a modern TC1150 300 HP Cone crusher with the highly efficient LJ-TSV 6×20 3 deck screen. This 300 HP cone utilizes high-efficiency roller bearings and boasts several notable advancements that enhance performance and functionality. Key features include automated cone controls and larger closed side settings and is rubber isolation mounted on a heavy-duty chassis frame.

The LJ-TSV 6 x 20 3 deck screen, known for its efficient, high g-force El-Jay® oval stroke motion handles heavy deck loads. The design also features more steel in the “rock zone” for industry-leading durability. The screen can be positioned at 0° or 2.5° to best fit the application. Patented deck deflector plate option increases capacity an additional 10%.

Get More InfoApplication: Aggregate

Manufacturer: Cedarapids

Configuration: Portable (Wheeled)

Model: Cedarapids CRC1150S Portable Cone Crusher Plant

New/Used: New

Learn more about the CRC1150S Portable Cone & Screen Plant in the following animation.

Standard Features

Optional Equipment

The CRC1150S cone crusher plant comes standard with a tandem axle spring suspension with multiple axle configurations available to meet a variety of road regulations including a triple axle spring suspension with drop-down rear stabilizing legs or oversized 315/80 R22.5 tires.

The patent-pending screen drive on the CRC1150S allows for an unrestricted screen motion eliminating belt tensioner maintenance. It also features a walk over screen drive for easy access, folding handrails for transport, and a removable top step for the driveshaft access.

Cedarapids crushing and screening plants are designed with maintenance in mind. The CRC1150S cone crusher features conveniently located grease banks and a ground access cone lubrication module

The CRC1150s portable cone crushing plant is equipped with a 3-ply conveyor belt with a vulcanized belt splice and a primary style belt wiper which is driven by a 15 hp (11kW) electric motor and shaft mount gearbox.

With almost 200 years of crushing and screening manufacturing experience, Cedarapids delivers rugged, field-proven crushing and screening solutions. Cedarapids® Crushing & Screening Plants offer the essential flexibility, control, and reliability to make the difference – whatever the application, wherever the location.

Cedarapids® Crushing & Screening Solutions Cedarapids® provides a complete range of crushing and screening equipment to customers around the world operating in four key industries: mining. aggregates. demolition and recycling. To date they have thousands of plants operating througout the globe are known for equipment designs and technologies which are built to last.

“With Cedarapids®, you don’t just get best-in-class engineering technology. You get the service, training and support to match. They understand owners needs to maximize productivity and control operating costs across the working life of every piece of equipment. This means you can count on engineering technology that delivers in terms of maintenance access, longevity, and cost per tonne.”

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |