Additional information

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |

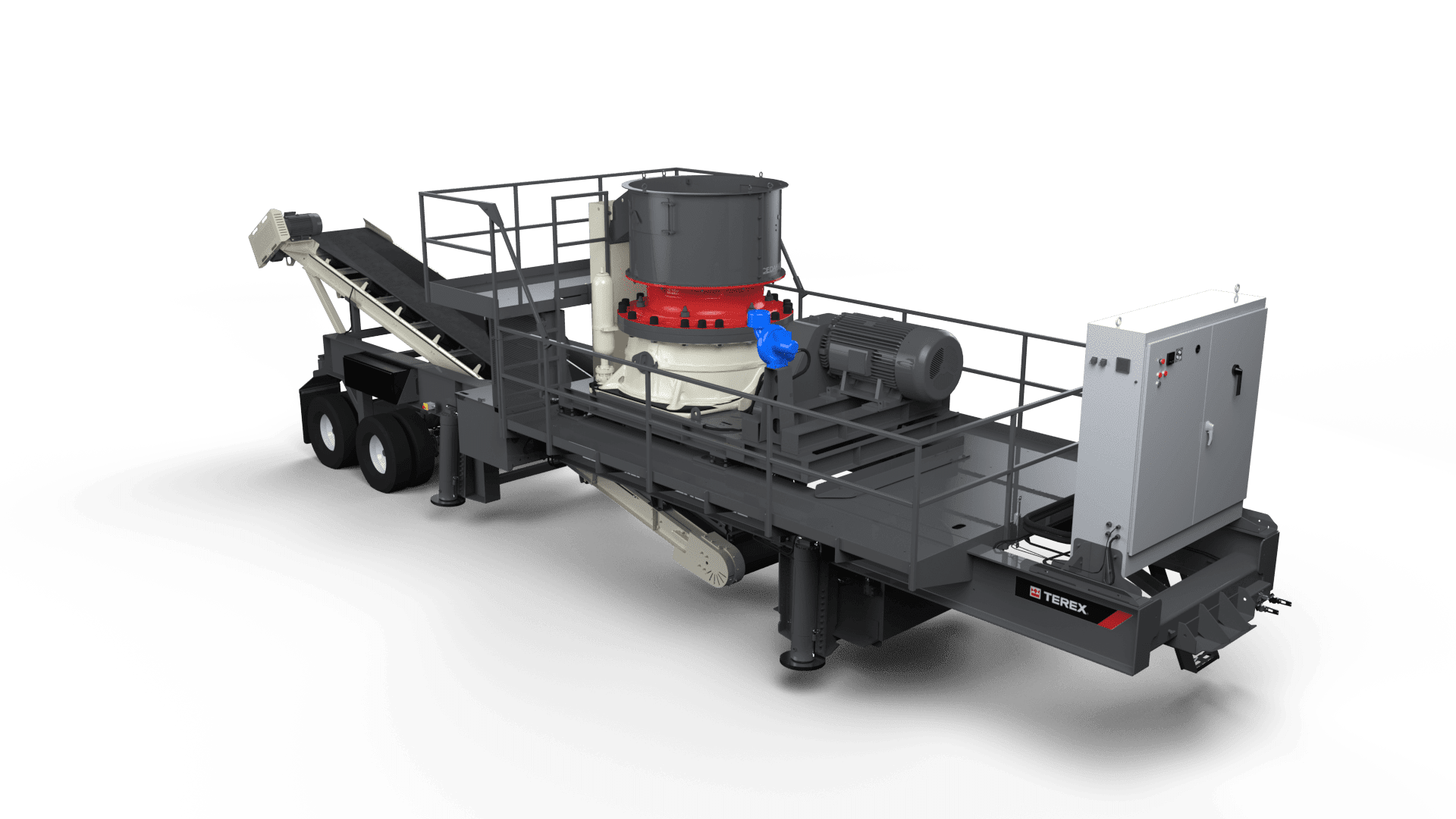

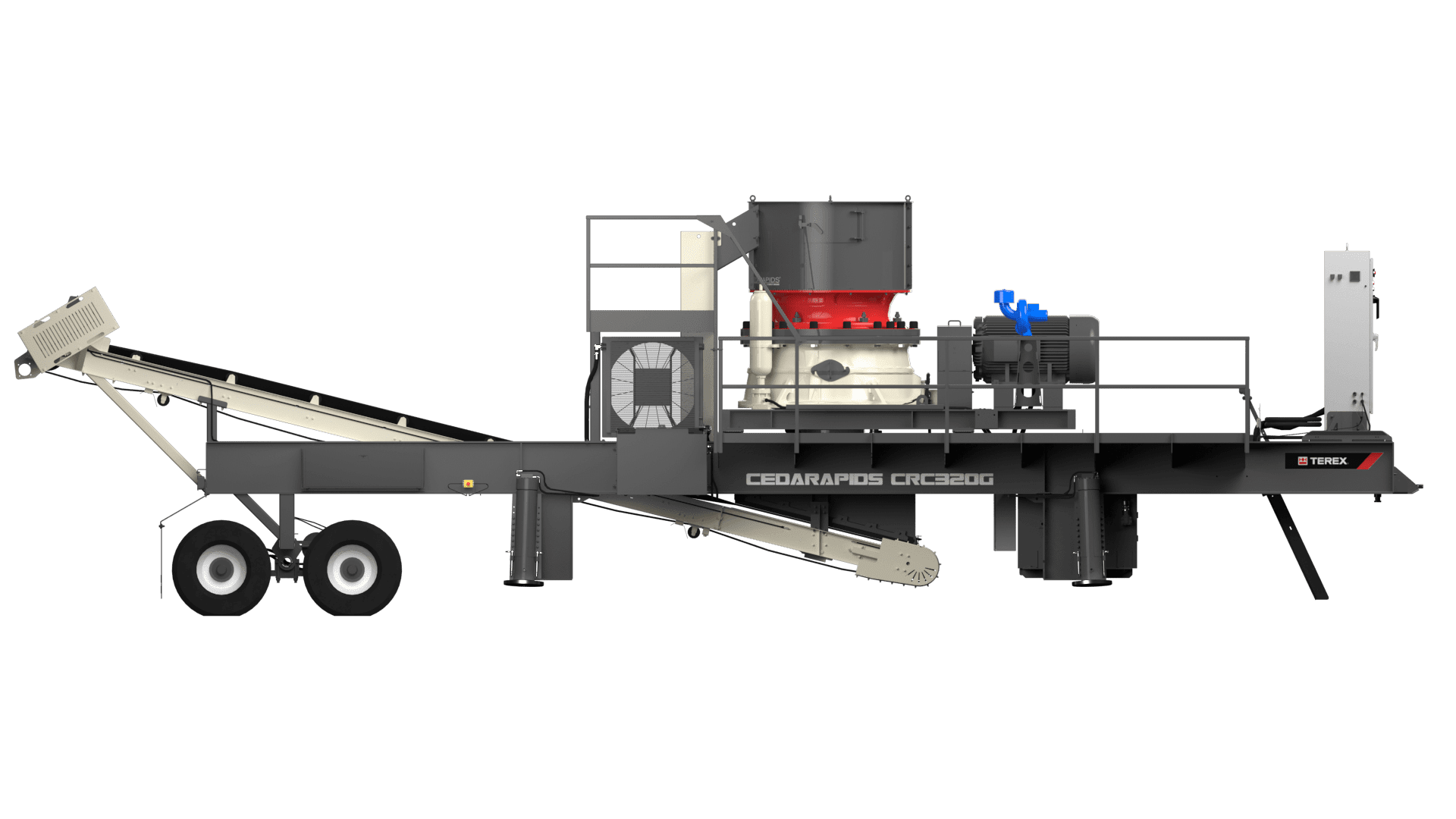

The CRC320 combines the TG320 cone and a 15 hp, 42” wide discharge conveyor on a portable all electric chassis. The crusher is fitted with an overflow chute and removable overflow panel so the overflow can buffer feed surges in a closed circuit application. The trailer width and length allow easy movement from site to site. The plant has a variety of jack options available from simple crank landing to unique patent-pending “canted” run-on jacks that stabilizes the movement of the crusher.

Get More InfoApplication: Aggregate

Manufacturer: Cedarapids

Configuration: Portable (Wheeled)

Model: Cedarapids CRC320 Portable Cone Crusher Plant

New/Used: New

Standard Features

Optional Equipment

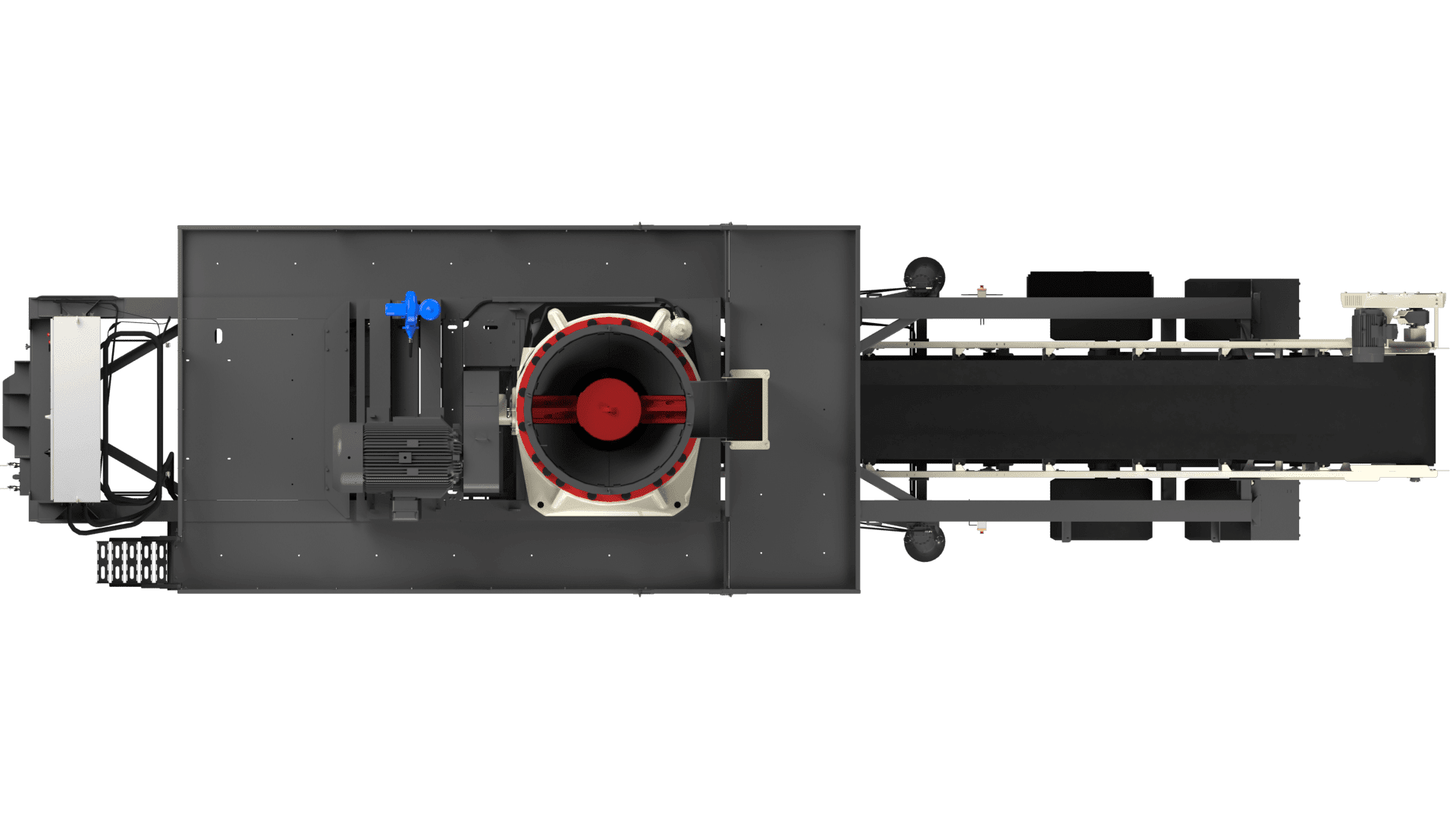

The bronze bushing technology of the TG320 cone enables the operator to quickly and easily alter the eccentric throw of the cone, on-site, simply by rotating the eccentric bushing. Combined with multiple liners, the CRC320 cone plant matches most any application.

The crusher is fitted with an overflow chute and removable overflow panel so the overflow can buffer feed surges in a closed circuit application.

Service platforms with wide walkways allow easy and safe access for maintenance and inspection. The bronze bushing technology of the TG320 cone enables the operator to quickly and easily alter the eccentric throw of the cone, on-site, simply by rotating the eccentric bushing.

The CRC320 cone crusher is equipped with a 42” x 34’6” (1067 x 10,515 mm), 3-ply conveyor belt with vulcanized belt splice and primary style belt wiper which is driven by a 15 hp (11kW) electric motor and shaft mount gearbox.

With almost 200 years of crushing and screening manufacturing experience, Cedarapids delivers rugged, field-proven crushing and screening solutions. Cedarapids® Crushing & Screening Plants offer the essential flexibility, control, and reliability to make the difference – whatever the application, wherever the location.

Cedarapids® Crushing & Screening Solutions Cedarapids® provides a complete range of crushing and screening equipment to customers around the world operating in four key industries: mining. aggregates. demolition and recycling. To date they have thousands of plants operating througout the globe are known for equipment designs and technologies which are built to last.

“With Cedarapids®, you don’t just get best-in-class engineering technology. You get the service, training and support to match. They understand owners needs to maximize productivity and control operating costs across the working life of every piece of equipment. This means you can count on engineering technology that delivers in terms of maintenance access, longevity, and cost per tonne.”

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |