Additional information

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |

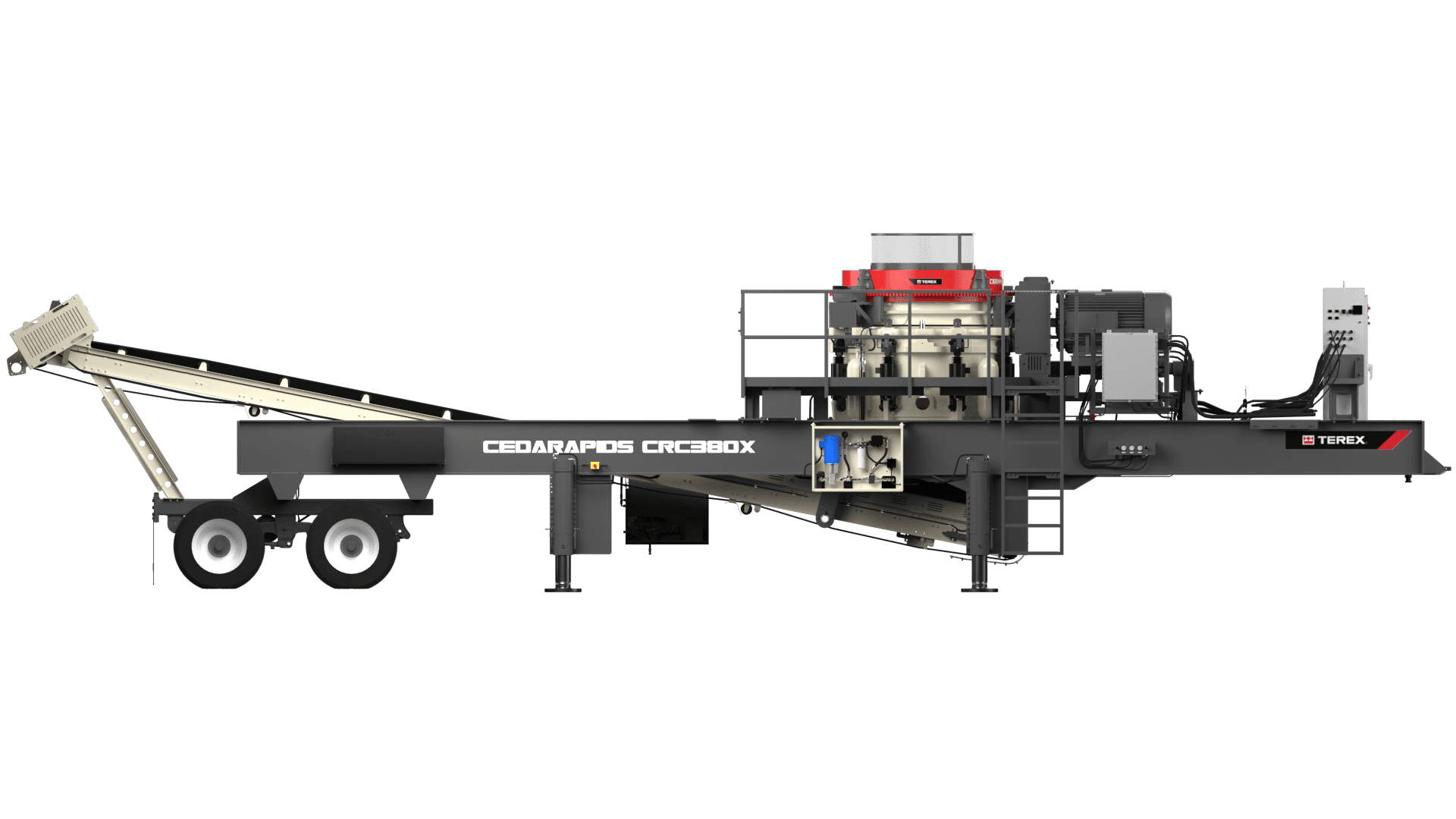

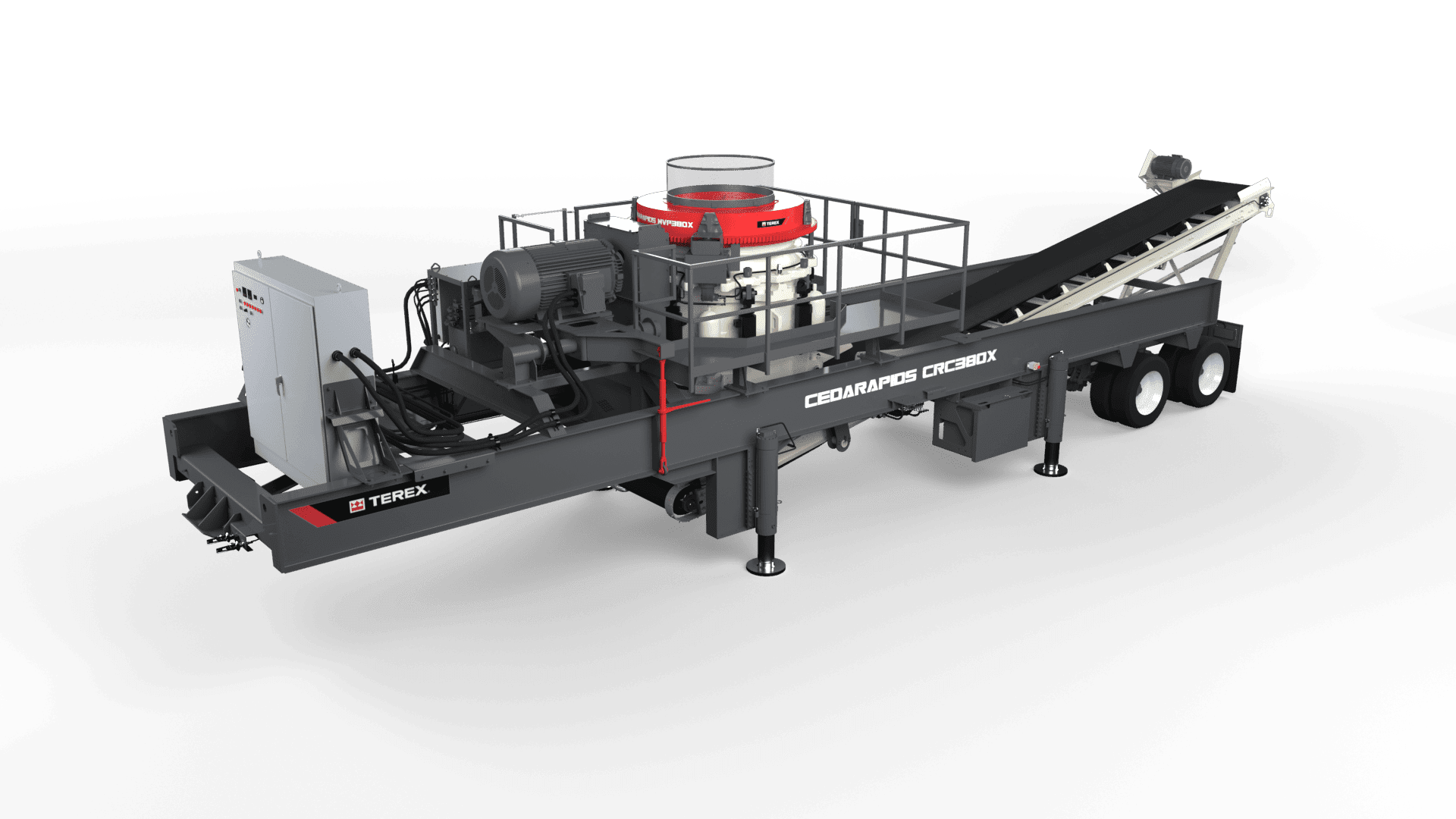

“The Cedarapids® CRC380X cone plant is built for portability, especially for applications involving hard abrasive materials. This open circuit plant can be tied in with any portable crushing operation. They are commonly set up in secondary, tertiary, and quaternary crushing positions. The CRC380X is an all electric plant which can easily be tied into new or existing systems. CRC380X plants are available with a variety of options including feed conveyors and extra length undercrusher conveyors.

Get More InfoApplication: Aggregate

Manufacturer: Cedarapids

Configuration: Portable (Wheeled)

Model: Cedarapids CRC380X Portable Cone Crusher Plant

New/Used: New

Standard Features

Optional Equipment

*Requires triple axle option and hydraulic leveling or run-on jacks option”

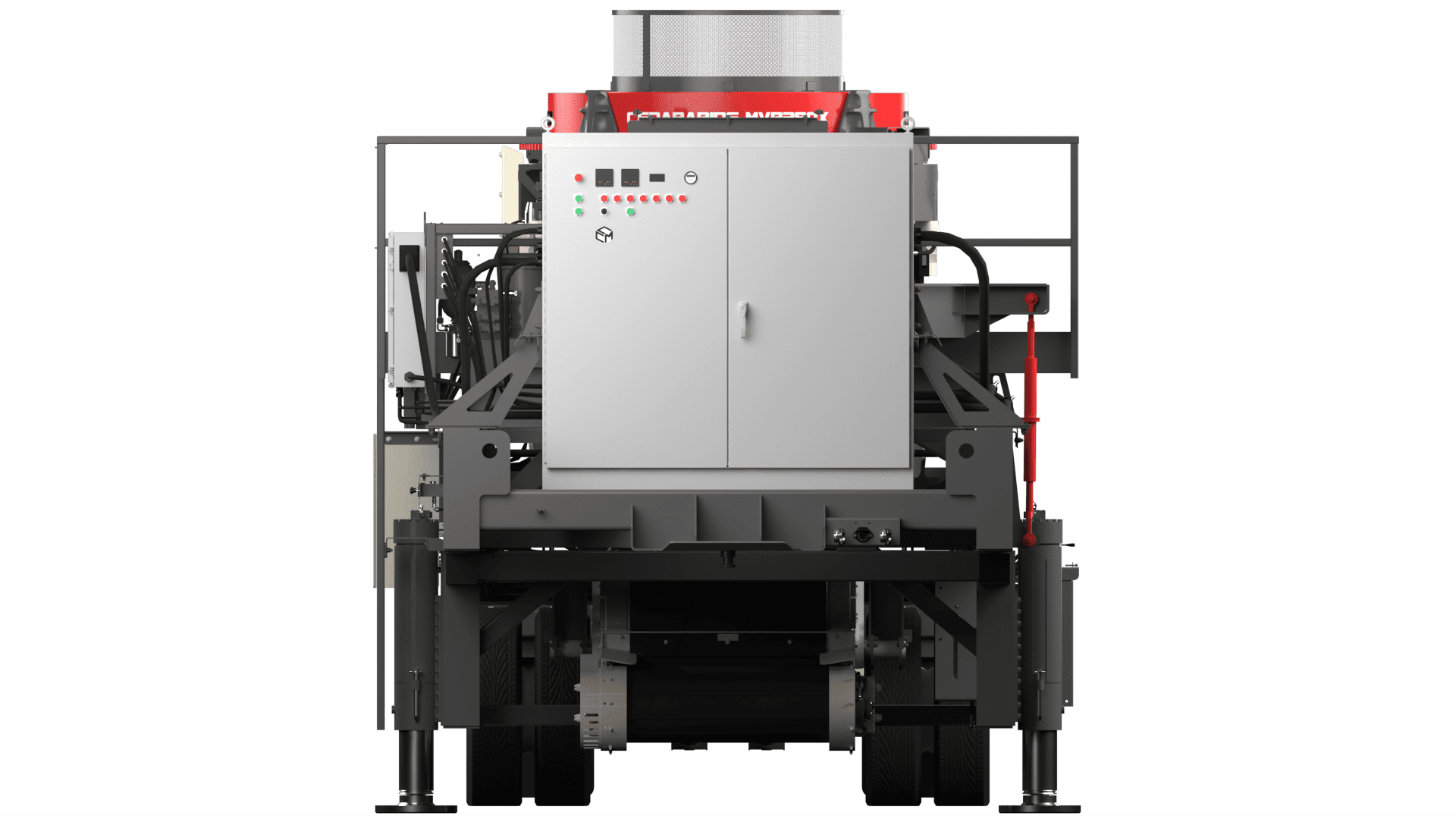

Cedarapids crushing and screening plants are designed with maintenance in mind. The CRC380X features ratchet cone drive belt tensioning, conveniently located grease banks, ground access cone lubrication module, and a large undercrusher hinged access panel.

The CRC320 cone crusher is designed with a 42” x 34’6” (1067 x 10,515 mm), 3-ply conveyor belt with vulcanized belt splice and a primary style belt wiper that is driven by a 15 hp (11kW) electric motor and shaft mount gearbox.

The CRC320 cone crusher plant can come with multiple axle configurations available to meet a variety of road regulations including triple axle spring suspension with drop-down rear

stabilizing legs or oversized 315/80 R22.5 tires.

The removable CCM automatic switchgear panel offers improved safety, reduced downtime, easy one-touch control for single plant or multi-plant operation, quick diagnostics, safe 24-volt control circuits, and small interplant cable, and built-in automation and optimization to maximize production.

With almost 200 years of crushing and screening manufacturing experience, Cedarapids delivers rugged, field-proven crushing and screening solutions. Cedarapids® Crushing & Screening Plants offer the essential flexibility, control, and reliability to make the difference – whatever the application, wherever the location.

Cedarapids® Crushing & Screening Solutions Cedarapids® provides a complete range of crushing and screening equipment to customers around the world operating in four key industries: mining. aggregates. demolition and recycling. To date they have thousands of plants operating througout the globe are known for equipment designs and technologies which are built to last.

“With Cedarapids®, you don’t just get best-in-class engineering technology. You get the service, training and support to match. They understand owners needs to maximize productivity and control operating costs across the working life of every piece of equipment. This means you can count on engineering technology that delivers in terms of maintenance access, longevity, and cost per tonne.”

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |