Additional information

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |

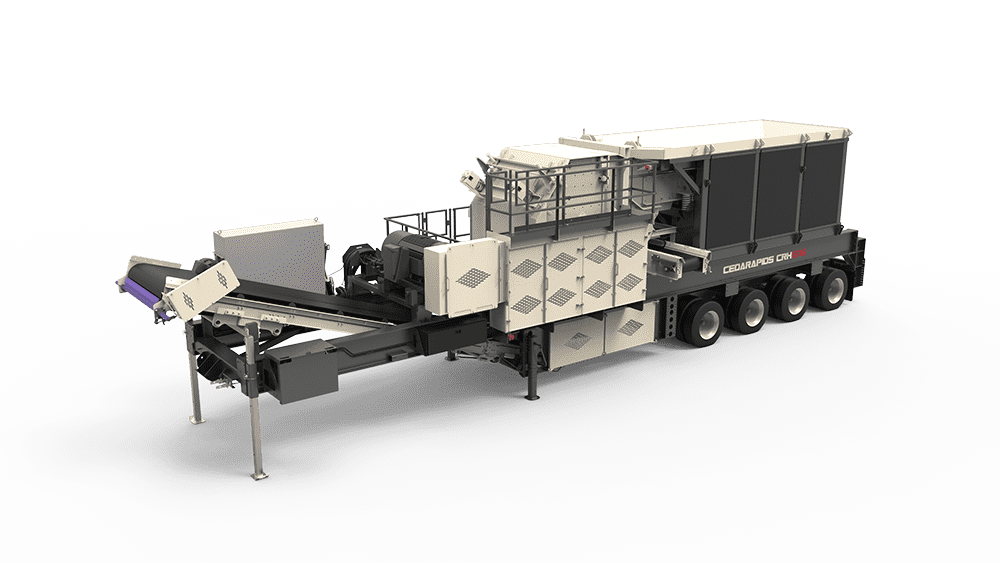

The CRH1316 HSI plant is tough to match in productivity. This portable plant features the Cedarapids IP1316 impact crusher, with its massive rotor, quick change impact bars, and heavy monoblock primary curtain, all designed for years of tough primary crushing. This plant has the capacity you need to lead off most any large portable operation.

Get More InfoApplication: Aggregate

Manufacturer: Cedarapids

Configuration: Portable (Wheeled)

Model: Cedarapids CRH1316R Portable Impact Crusher Plant (HSI)

New/Used: New

Standard Features

The CRH1313R horizontal shaft impact crusher is designed with a high capacity IP1316 crusher with a 50” x 48” high inertia rotor. The large 50” diameter rotor can withstand and take larger bites on heavy feeds.

Design features such as the patent-pending hinged return chute, hinged magnet support, and bi-directional metal reject chute, offer a quick and tool-less set up of the entire plant in one hour or less with no manual assembly or boom lifts required.

The CRH1313R impact crusher is powered by a tier 4, 450 hp (335kW) diesel engine with a hydraulic clutch split drive to the crusher and generator. The high horsepower combined with an efficient direct crusher drive handles maximum production without bogging down.

The heavy-duty 600 PIW vulcanized belt is 2x stronger than a standard 3 ply belt. It can handle high-velocity material discharge and provides a large discharge clearance.

With almost 200 years of crushing and screening manufacturing experience, Cedarapids delivers rugged, field-proven crushing and screening solutions. Cedarapids® Crushing & Screening Plants offer the essential flexibility, control, and reliability to make the difference – whatever the application, wherever the location.

Cedarapids® Crushing & Screening Solutions Cedarapids® provides a complete range of crushing and screening equipment to customers around the world operating in four key industries: mining. aggregates. demolition and recycling. To date they have thousands of plants operating througout the globe are known for equipment designs and technologies which are built to last.

“With Cedarapids®, you don’t just get best-in-class engineering technology. You get the service, training and support to match. They understand owners needs to maximize productivity and control operating costs across the working life of every piece of equipment. This means you can count on engineering technology that delivers in terms of maintenance access, longevity, and cost per tonne.”

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| New/Used |